|

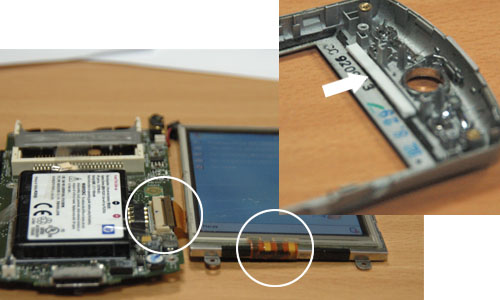

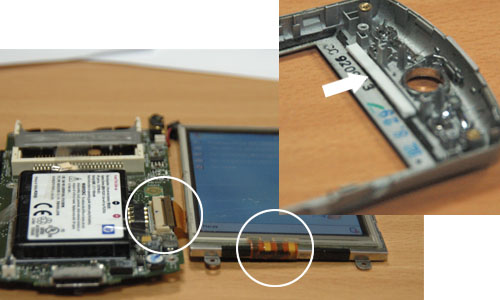

To the Editor HPCru received a letter from our reader Valeriy Kuzmin, with a proposal to publish a short article, a recommendation for self-repair screen PDA HP iPAQ h2210, lost their sensory abilities. In general, no hesitation, we decided to expand the subject headings you liked diy and share in her part of it, without doubt, an interesting experience. So now we ask you to send for "diy" not only stories about the original decisions on the basis of the CCP, but also practical advice on repairs, maintenance and other everyday realities - all of this, preferably with photos. E-mail as usual on editor@hpc.ru. And now - to the point. Anticipating a little say that repeating this experiment at home, we would recommend only to those who have seen electronic devices "inside out" and owns nizhenazvannymi tools:) Other, not self-confidence, we advise all the same to apply to service centers . Editorial HPCru not responsible for the failed experiment in self-repairing screen. I'm sure many of you know my problem - problem with the reaction of the touchscreen iPAQ h2210 clicking on the stylus. And everything started with the failures gauge display, and then began to disappear sensitivity. A little later, a long time "numb" the bottom of the screen (approximately 5-7 mm from the bottom edge), and the surviving area kolbasit as usual: it responds to a stylus, then no. About a month later I was pretty tired, so we had to take the tool and dissect his "Ike". As it turned out, it's not complicated. Dissection you will need the same tool that is used for opening mobile phone: a small Phillips screwdriver and a small hexagon (if someone does say something, then my tools were written + NO.0x30 and * T-6x30, respectively). Buy such kits can usually be in the shops that sell cell phones. So, free up space on the dismantling of any metal objects. Prepare a small container for storing and bolt shurupchikov. In addition, you will need an eraser stationery and office tape. Proceed. First and foremost, do a full backup of "aiki". I have done this operation with the built-in ActiveSync. Our goal is to touch the screen. Carefully separate the sides (if someone still have:). Under the sidewalls have two bolt, two bolt found in the bottom of the back cover. To delete them, we need the hexagon. Another four bolt find the battery compartment. Now that you have removed all bolts, note the four clips that are shot on site sides - two on each side. Using a screwdriver, you will easily be able to separate the top cover. But that's not all. The board has two screws in black, placed at the top. For their retirement will need Phillips screwdriver. But before you remove the card, you must disable the connector shield (see photo - left circle).

|

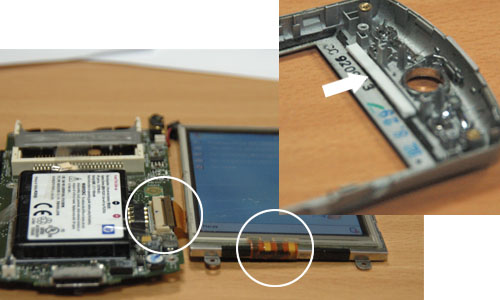

To do this accurately poddevaem screwdriver brown latch and we press it upwards. It should be fairly easy to climb. We can then take the train. Again, do it very carefully. If the train does not leave when an easy effort, then pay attention to the "ears" that are at the end of it. Carefully lift them, and the trail is easy to jump out of the slot. Now look in the upper right corner of the board. There is a headphone jack, under which the hidden microphone. In order to pay off from the screen, headphone jack should "get out" of engagement with the body. With this you can easily manage.Microphone freely lies in deepening the housing and connected to the board by wires. If you can not easily pull it together with the board, you'll have to disconnect from the connector. After separating the board we will see, in fact, our goal - the screen. But with him we still need to tinker. Screen engages c-hull in six locations: two latches on each side and two hooks at the top. In addition, he secured with two screws at the bottom. First, of course, need to remove the screws with a Phillips screwdriver, then carefully remove the screen. I've done it cavalierly, but you do so I do not recommend. Simply tilt the hull sides and the screen should come very easily. By the way, can immediately clean up the contacts of the train. To do this they need to carefully rub the eraser. Typically, treatment is noticeable to the eye - contact us begin to shine like new. Flip the screen and connect it to the board. Now we need to incorporate this design. Secure on-board battery, as I did, with a thin stationery adhesive tape, which can be seen in the photo. But to our "guts" have earned, we must also bypass the lock. It is located between the battery and CF-plugs. In my case it was a small white buttons. Perhaps you have a color will be different. I clicked on it a small cube, carved from an eraser and pressed against it by using the same stationery adhesive tape, which also can be seen in the photo. Then click the button Power, which is now located in the upper left-hand side, on the back side of the board. It can easily find a finger. If you need to revitalize another button and Reset, then it is right in front of you, in the lower left side of the board. Now, most importantly, what are silent all the service centers for fear of losing customers. The whole problem (at least in three cured my machines, which operate to this day) is the loss of contact in the compound loop with a touch screen coating (see photo - right circle). To me this epiphany came upon an hour after picking in the interiors of the first "aiki". In order to make sure that in your case, it is a loss of contact, take an eraser and put it in this area. However, the need to put in such a way that he did not hide the gray bar at the bottom of the screen. Lightly press down on it and try to poke the stylus in those parts of the screen that you are numb or problematic or incorrect positioning. If that's the problem described, this should make perfect. Now proceed to the Responsible of the operation. With a very sharp knife and you have to cut a thin strip of eraser thickness of about a millimeter. It is important that you did it very smoothly. As the eraser is too broad for our purposes, you need to reduce the width of the strip to about four millimeters. The length of the pick up yourself and place the eraser as shown in the second photo (the location of the pressure pads pointed white arrow). In order to permit assembly eraser not slipped from its place, it must be something to fix. It is better to make some dolgosohnuschim glue. Dolgosohnuschim so that if the assembly does not fully recover the screen, eraser could move to a more suitable place. When assembling do not forget, please, about the microphone, if you disable it from the connector, and also about the numerous pieces of tape if you used it for fixing the battery and lock bypass. In addition, the variant, when disassembly would lead to "hard-rezet, for example, because of the shrunken auxiliary battery. In this case, do not forget that, if the restoration of the backup-file ActiveSync cavalierly declares that it can not do because of a change locale, you need to simply install the Russification and only then start the recovery process. Good luck and thank you for your attention! Sources, Materials: